Introduction: The Unique Challenges of the Las Vegas Desert Climate for Outdoor Signage

Las Vegas signage lives under an unforgiving sky. Triple‑digit air temperatures, extreme UV, low humidity, abrasive dust, sudden monsoon bursts, and powerful gusts all conspire to fade inks, warp substrates, and tear poorly finished edges. If you want durable outdoor signage Las Vegas businesses can rely on, material and finishing choices must be made for the desert first, aesthetics second.

Key stressors to plan for include:

- UV index regularly hitting 10–11, accelerating pigment fade and plastic degradation

- Surface temperatures exceeding 160°F on dark substrates, softening banner vinyl and adhesives

- Rapid thermal swings from scorching days to cooler nights, causing expansion and contraction

- Wind gusts 40–60 mph funneling between buildings and across open lots, stressing grommets and poles

- Fine dust acting like sandpaper on laminates and hinges, plus sudden downpours during monsoon season

These conditions punish the wrong build. Economy PVC can warp or “chalk” in UV. Standard solvent inks fade quickly without UV laminate, while low-temp adhesives creep or delaminate under heat. Banners without reinforced hems or webbing can rip at the grommets; solid vinyls act like sails in gusts unless you opt for mesh. Selecting UV resistant sign materials and sun resistant printing solutions, paired with heat resistant banner printing practices, is the difference between a one-week wonder and a season-long performer.

Consider real-world use cases. Sidewalk A-frames on the Strip need rigid panels like aluminum composite (ACM) and stainless hardware to resist heat and corrosion. Fence-mounted event banners do better in mesh with reinforced hems, corner grommets, and bungees that flex under gusts. For valet or cab-stand towers, look for weatherproof outdoor graphics with UV-cured or latex inks, anti-graffiti laminates, and powder-coated frames—true heavy duty event signage that stands up to both sun and crowds.

Design One Printing sees these challenges daily and builds for them. Located minutes from the Strip, the team can recommend ACM, HDPE, premium cast vinyl with UV overlaminate, and mesh banner options, finished with sewn hems, webbing, and UV-rated fasteners—often with same-day turnaround for conventions and outdoor activations. For artwork that scales cleanly on large pieces, explore their guidance on high-quality large format printing to pair the right file prep with the right material.

Key Properties of High-Performance Heat-Resistant Printing Materials

In the Mojave sun, materials face extreme UV exposure, surface temperatures that can exceed 160°F on dark substrates, and abrasive dust. For durable outdoor signage Las Vegas marketers can rely on, prioritize properties that prevent fading, warping, adhesive failure, and tearing over long dwell times.

- UV stability: Choose UV resistant sign materials paired with UV-cured or latex inks and UV-protective overlaminates for colorfastness and crack resistance. Sun resistant printing solutions with built-in inhibitors extend life on south- and west-facing installs.

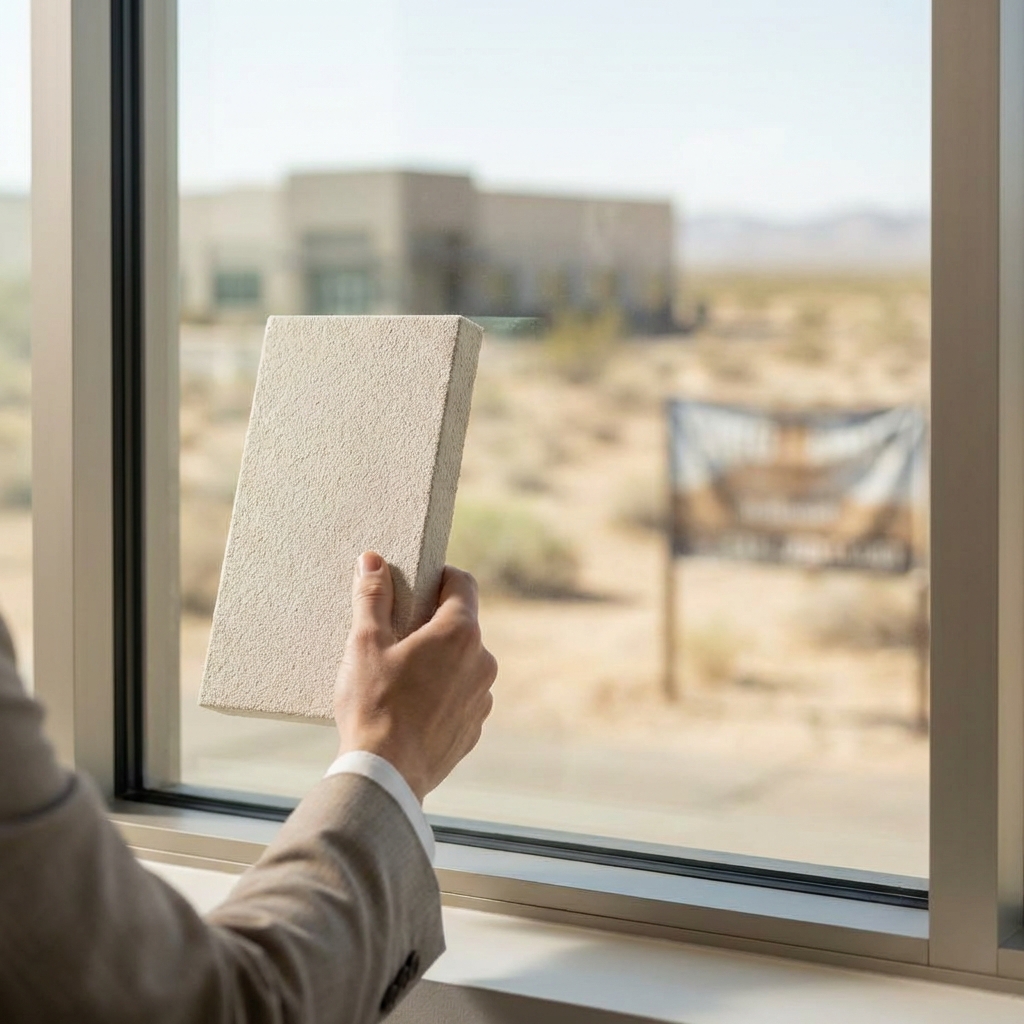

- Thermal stability: Look for substrates with low thermal expansion and high glass transition temperatures to resist bowing. Aluminum composite (ACM), polycarbonate, and HDPE outperform expanded PVC or foam boards in sustained heat.

- Weatherproofing: For weatherproof outdoor graphics, ensure water resistance, sealed edges, and corrosion-resistant hardware. On banners, blockout scrim vinyl and welded hems limit moisture intrusion and edge curl.

- Wind load tolerance: In high-gust corridors, mesh banner (e.g., 70/30 airflow) or perforated window film reduces sail effect. Reinforced corners, perimeter webbing, and properly spaced grommets are essential for heavy duty event signage.

- Adhesive performance: Use high-tack, solvent-acrylic adhesives rated for elevated temperatures on metals, textured stucco, and low-energy plastics. For wraps and decals, cast films with conformable liners maintain bond through thermal cycling.

- Abrasion and soil resistance: Dust and hand contact demand rugged overlaminates—matte for glare control, anti-graffiti where cleaning is frequent. Edge finishing and rounded corners reduce peel points.

Material picks that perform in Las Vegas include 18-oz blockout scrim for heat resistant banner printing; mesh for fence lines and outdoor queues; ACM panels for directional and branding signs; and 4–6 mm corrugated polypropylene for short-term stakes. For decals and equipment labels, opt for cast vinyl with a UV laminate; for tension frames, choose dye-sub polyester with UV inhibitors and silicone edge finishing.

Design One Printing helps specify the right stack—substrate, ink system, laminate, and finishing—for the install site and duration, and can deliver weather-resistant outdoor banners same-day when timelines tighten. Hardware matters too: stainless fasteners, expansion slots for rigid panels, and properly rated pole pockets protect installs from thermal movement. Field-tested material samples and on-the-Strip support reduce risk for time-critical convention and event rollouts.

Best Materials for Outdoor Banners and Large Format Signage

In the Mojave sun, material choice is the difference between signage that pops all week and signage that curls, cracks, or fades by day two. For durable outdoor signage Las Vegas events can trust, prioritize substrates and inks engineered for UV, heat, dust, and sudden wind gusts. Look for UV resistant sign materials paired with UV-cured or latex inks, which resist fading and maintain color density under relentless sun.

For banners, 13 oz scrim vinyl is the versatile workhorse for short to mid-term installs, while 18 oz provides heavy duty event signage that resists tearing on larger spans or windy sites. Blockout vinyl prevents show-through for double-sided street pole banners, and mesh vinyl allows air to pass through on fences, stages, and scaffolding. Reinforced, welded hems, nickel grommets, and pole pockets reduce stress points in high heat; optional liquid UV clear coats extend life without adding stiffness that can cause cracking.

Large format signs benefit from rigid substrates that shrug off heat. Aluminum composite (ACM/Dibond) delivers long-term dimensional stability for building exteriors and wayfinding, while solid aluminum is ideal for parking and compliance signs. PVC (Sintra) works for seasonal campaigns but can soften in extreme heat; choose thicker gauges and shaded placements. Corrugated plastic (Coroplast) is budget-friendly for short-term outdoor graphics, and polycarbonate offers impact resistance for high-traffic zones; add a UV overlaminate for sun resistant printing solutions and easier cleaning.

Adhesive graphics require films and glues made for desert temperatures. Cast vinyl conforms and lasts longer on textured or curved surfaces, making it preferable to calendered films for heat resistant banner printing and wraps. High-tack adhesives grip stucco and brick, while perforated window film balances storefront visibility with bold branding. Always specify overlaminates rated for exterior use to deliver weatherproof outdoor graphics that resist abrasion and chemicals.

Quick picks based on use case:

- One- to three-day events: 13 oz vinyl banners, Coroplast signs, calendered vinyl decals with UV inks.

- Weeklong conventions/festivals: 18 oz banners with welded hems, mesh for fencing, ACM for directional signs, cast vinyl decals with UV laminate.

- Multi-month installations: ACM or aluminum with UV laminate, cast vinyl films, blockout banners on pole hardware.

Design One Printing sources desert-ready materials and prints with UV-stable processes, then finishes banners and signs for longevity with proper hems, grommets, and pockets. Located minutes from the Strip, the team can turn around same-day outdoor pieces for last-minute activations while advising on the best substrate and finishing to withstand sun, heat, and wind.

Understanding the Role of UV-Protective Laminates and Specialized Inks

In Las Vegas, UV intensity and surface temperatures routinely push signage beyond normal limits, accelerating fading, cracking, and adhesive failure. UV-protective laminates act like a sunscreen for prints, absorbing and filtering wavelengths that break down pigments and vinyl. For Durable outdoor signage Las Vegas projects, a proper overlaminate can double or triple color life compared to unlaminated graphics, while also improving abrasion resistance.

Select the laminate to match both your inkset and substrate. Cast PVC and polyurethane films withstand heat and expansion better than calendered PVC, making them ideal for metal panels, vehicles, and long-term installs. Gloss finishes deliver the highest color vibrancy, while matte reduces glare for readability in bright sun. In desert conditions, 2–3 mil UV laminates with high-temperature rating and solvent-resistant adhesives maintain bond strength and resist edge lift.

Practical pairings that perform in the desert heat:

- Long-term panels and monument signs: cast vinyl prints with 2 mil cast UV overlaminate (e.g., gloss 8518 or matte 8520) on aluminum composite; edge seal for sand and moisture defense.

- Short-term event wayfinding: calendered vinyl with 3 mil UV matte lam for easy removal after 6–12 months.

- Heat resistant banner printing: 13–18 oz scrim banner with UV-stable inks; for wind-exposed sites, use mesh banner to reduce stress—lamination is typically unnecessary.

- Decals and sidewalks: textured, UL-rated anti-slip laminate for weatherproof outdoor graphics and safer foot traffic.

Specialized inks matter as much as the laminate. Latex inks offer strong outdoor durability, flexibility for folding and heat, and low odor—great for fast, heavy duty event signage. UV-curable inks are extremely abrasion resistant and crisp but can be less flexible on tightly rolled pieces; lamination helps mitigate micro-cracking. Eco-solvent inks provide rich color and good sun resistance; pairing with a UV laminate slows the typical magenta/yellow fade in intense sun.

Design One Printing combines sun resistant printing solutions—like latex or UV inksets—with the right laminate stack for Las Vegas conditions, then finishes with hems, grommets, and edge sealing. For tight timelines near the Strip, they can recommend UV resistant sign materials, produce test swatches, and turn same-day graphics that hold up outdoors without sacrificing color or readability.

Common Applications: Event Wayfinding, Storefronts, and Directional Signs

Whether you’re guiding attendees across a sprawling convention campus or welcoming foot traffic to a retail entrance, durable outdoor signage Las Vegas demands materials that can withstand extreme sun, heat, and wind. Wayfinding and directional signs must remain legible at distance, resist fading, and stay secured in gusts common to the valley. Prioritizing UV resistant sign materials, reinforced finishes, and the right hardware will keep messages crisp throughout multi-day events and ongoing storefront promotions.

For event wayfinding, choose substrates based on duration and placement. Short-term directional stakes and A‑frames perform well with 4mm corrugated plastic printed with UV-cured inks; they’re light, cost-effective, and weatherproof for multi-day use. For higher-traffic zones, fence lines, and shuttle queues, opt for heat resistant banner printing on 70/30 mesh vinyl to relieve wind load, with heat‑welded hems, webbing reinforcement, and stainless grommets. Nighttime visibility improves with reflective vinyl overlays on aluminum composite for heavy duty event signage that won’t warp under desert sun.

Recommended pairings by application:

- Temporary directional signs: 4mm coroplast + UV direct print; A‑frame inserts for quick swaps; sand or water‑base stabilizers.

- Long-term campus and parking: 3mm aluminum composite (ACM) or .040 aluminum + reflective sheeting + anti‑graffiti laminate.

- Barricades and fences: 8–10 oz mesh vinyl banners + pole pockets or reinforced hems; avoid wind slits—mesh performs better.

- Sidewalk and plaza arrows: textured aluminum-backed floor graphics with high‑tack adhesive and slip‑resistant, UV laminate.

- Light pole wayfinding: double‑sided 18 oz vinyl pole banners + spring‑loaded arms for gust mitigation.

Storefronts benefit from sun resistant printing solutions that preserve brand color. South‑facing facades do best with ACM panels rather than PVC, which can soften in sustained heat. For windows, perforated window film with UV laminate offers one‑way visibility while cutting glare; cast vinyl lettering and decals last longer than calendared films on hot glass. If you need frequent promotions, consider changeable A‑frames or rail‑mounted poster frames with weatherproof outdoor graphics.

Design One Printing helps teams choose the right materials and finishes for Las Vegas conditions and deadlines, from mesh banners and ACM panels to window perf and reflective wayfinding. Located minutes from the Strip, they offer same-day and next-day turnaround for conventions and storefront needs, with hardware options and finishing that keep signage secure, vibrant, and event-ready.

Installation Best Practices for Signage Exposed to Extreme Heat

In the Mojave sun, installation can make or break durable outdoor signage Las Vegas relies on. Plan for thermal expansion, gusty winds, and surfaces that can exceed 160°F. Prioritize mechanical fastening, airflow, and flexible connections that relieve stress as temperatures swing from dawn to late afternoon.

For rigid panels, use stainless steel or powder‑coated aluminum hardware and slotted holes to allow movement in heat. Aluminum composite (ACM) performs well; avoid expanded PVC, which can warp. Add 3/8–1/2 inch spacers so panels don’t sit flush on heat‑soaked walls, and vent lightboxes to prevent heat buildup behind the graphic.

For banners, design attachments to distribute load. Mesh is superior to wind slits—pair 2-inch reinforced hems and seatbelt‑style perimeter webbing with grommets every 12 inches. Use bungee/shock cords or adjustable turnbuckles at corners to keep tension consistent without tearing, a best practice for heat resistant banner printing at venues like the Las Vegas Convention Center.

Adhesive applications demand extra care in extreme heat:

- Clean with isopropyl alcohol and use adhesion promoters on low‑energy plastics; dust and sunscreen residue ruin bonds fast.

- Choose high‑temperature acrylic tapes or urethane adhesives rated for desert conditions; avoid generic foam tape.

- Install early morning when surfaces are 60–90°F, then maintain firm pressure; allow 24–72 hours to fully cure.

- Seal graphic edges with laminate edge‑sealing tape to reduce UV and moisture intrusion for weatherproof outdoor graphics.

Temporary and freestanding setups need ballast and flexibility. Water-fillable bases, sandbags, or plate weights keep flags and sidewalk signs grounded; consider guy lines for tall towers. Avoid mounting directly to black metal rails—add standoffs to limit heat conduction, and re‑tension hardware after the first afternoon of sun.

Safety and longevity checkpoints:

- Engineer for local wind loads; choose heavier‑gauge posts and deeper footings for large panels and heavy duty event signage.

- Use UV‑stabilized or stainless steel zip ties and carabiners; inspect monthly for embrittlement.

- Schedule quarterly cleanings; dust and grit accelerate abrasion and fade even on UV resistant sign materials.

Design One Printing conducts site surveys, specifies hardware kits, and installs sun resistant printing solutions across the Valley—minutes from the Strip for urgent event needs. Their team pairs the right substrates with field‑tested mounting methods to keep graphics sharp and secure all season.

Conclusion: Ensuring Longevity with Professional Outdoor Printing Solutions

In the Mojave, heat, UV, wind, and dust work together to degrade outdoor graphics fast. Achieving durable outdoor signage Las Vegas relies on pairing the right substrate with the right print chemistry and hardware, not just a thicker banner. Prioritize UV resistant sign materials like aluminum composite (ACM), powder‑coated aluminum, and cast vinyls; avoid foam board and standard PVC for sun‑drenched installs where warping and brittleness can occur.

Ink and finishing choices matter just as much. UV‑cured and latex inks provide sun resistant printing solutions with strong colorfastness, especially when paired with a cast or polycarbonate UV overlaminate to resist abrasion from desert dust. For heat resistant banner printing, spec 18 oz scrim vinyl with welded hems and webbing, or use mesh vinyl to relieve wind load on fences and truss—wind slits are not recommended as they can become tear points. Use stainless steel hardware, powder‑coated frames, and high‑temperature adhesives to prevent failures above 110°F.

Quick spec checklist you can take to your printer:

- Banners: 18 oz scrim with welded hems, reinforced corners, and #2 or #3 spur grommets; 70/30 mesh for fences and parking decks; avoid wind slits.

- Rigid signs: 3–6 mm ACM with UV laminate; stainless stand‑offs or mechanical anchors; skip corrugated plastic for long, sun‑exposed runs.

- Decals: Cast vinyl with high‑tack, high‑temp adhesive and a UV overlaminate; edge seal for pressure‑washed or sandblasted zones.

- Sidewalk and floor graphics: Textured, slip‑resistant outdoor laminate rated for heat; clean concrete and use a primer sealer.

- Flags and tents: Tear‑resistant polyester with fiberglass poles and water/sand bases; double‑stitching at stress points.

- Maintenance: Quarterly rinse to remove alkaline dust, annual inspection of fasteners and tension, and rotate duplicates for year‑round installs.

When timelines are tight, partnering with a local shop that understands venue rules and desert conditions is the simplest way to protect your budget and brand. Design One Printing, minutes from the Las Vegas Strip, produces weatherproof outdoor graphics, heavy duty event signage, and large‑format banners with same‑day and next‑day turnaround for conventions and pop‑up installs. Their team can review exposure, wind conditions, mounting surfaces, and deadlines, then spec materials, inks, and coatings that maximize lifespan without over‑engineering. Bring your timeline, art, and site details, and they’ll deliver sun‑smart, field‑ready results that hold up from setup to strike—and beyond.

Contact us today at designoneprinting.com to see how we can help on your next project.